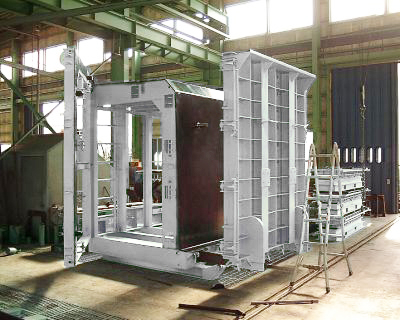

Precast Concrete Tilting Table

1.Ensures smooth demoulding through a stable tilting mechanism that releases panels with minimal stress.

2.Delivers improved surface quality with a flat working table and compatible vibration options.

3.Enhances operational safety with controlled tilting movement and steady handling during each step.

4.Supports a wide range of panel sizes thanks to a flexible table structure and adaptable layout.

5.Offers durable performance with reinforced steel construction and easy maintenance access.

6.Improves overall production efficiency by streamlining forming, compaction, and demoulding processes.

Overview and summary

The Precast Concrete Tilting Table is a purpose built casting platform that combines precise forming, controlled tilting action, and reliable handling to support efficient panel production. Its primary role is to facilitate safe pouring, effective compaction, and stress free demoulding, while delivering consistent surface flatness and dimensional accuracy. This introduction outlines typical use schemes, notable features, configurable parameters, core advantages, common applications, client feedback, company capability, and quality assurance. In summary, the Precast Concrete Tilting Table brings stability and workflow continuity to modern precast operations.

Function and introduction

The Precast Concrete Tilting Table functions as a stable base for casting panels that require a controlled angle for demoulding. The tilting mechanism permits gentle release of formed elements, reducing risk of edge damage and minimizing manual intervention. The system integrates with standard casting practices and supports a variety of panel profiles and finishing requirements.

Usage scheme and handling

Recommended usage pairs the table with conventional casting beds, simple handling fixtures, and planned demoulding sequences to preserve alignment and surface integrity. Operational guidance emphasizes balanced pouring, appropriate vibration strategy to consolidate mixes, and coordinated tilting and lifting procedures to protect finished panels during extraction.

Features and parameters

Key features include reinforced steel frame construction, precision flat top surface, robust hinge and locking assemblies, and adaptable mounting points for accessories. Surface treatment options and finishing methods are available to suit different production environments and exposure conditions. Modular accessories allow easy adaptation for varying panel formats and workflow layouts.

Advantages and performance benefits

Primary advantages focus on improved demoulding quality through controlled tilting, enhanced surface finish delivered by a flat working plane, and safer handling supported by steady mechanical motion. The table reduces manual handling risks, lowers rework needs by preserving edge integrity, and streamlines the casting to curing sequence to support steady output and predictable scheduling.

Applications and use cases

The tilting table is ideal for producing architectural façade panels, structural wall panels, insulated sandwich elements, and decorative precast components used in building and infrastructure projects. It suits both centralized precast yards and near site production where controlled demoulding improves installation readiness and reduces on site adjustments.

Customer feedback and testimonials

Clients report noticeable improvements in panel flatness, fewer surface repairs after demoulding, and smoother coordination between casting and handling teams. Feedback often highlights easier planning of production runs and quicker turnover of casting cycles when the tilting table is included in the process.

Company capability and service support

The manufacturer provides full fabrication capability, engineering consultation for layout optimization, and on site commissioning support. Service offerings include guidance on handling procedures, accessory selection to match plant requirements, and spare part provisioning to maintain continuous operation.

Reliability and quality assurance

Reliability stems from disciplined welding and machining practices, precision assembly checks, and practical validation under working conditions. Quality assurance emphasizes top surface flatness, hinge integrity, and long term resistance to wear, ensuring consistent performance across repeated production cycles.

Final summary of product advantage

Overall, the Precast Concrete Tilting Table is a durable and pragmatic solution for producers who value consistent panel quality, safer demoulding, and streamlined production flow. Its combination of precise engineering, adaptable configuration, and dependable field performance makes it a valuable asset for modern precast manufacturing.