Grouped Mold Assembly Speed Sets New Record

Grouped mold assembly speeds up and breaks records: Multiple enterprises' technological breakthroughs lead to a revolution in the efficiency of prefabricated buildings

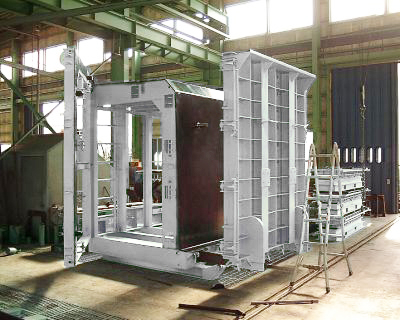

In the current era of accelerated upgrading of the prefabricated building industry, the group assembly mold, as the core equipment for prefabricated components production, has recently witnessed a period of concentrated technological breakthroughs. Companies such as Dezhou Haitian Machinery and Ai Li have successively achieved a jump in production efficiency. This equipment, often referred to in the industry as "battery assembly mold", is reconfiguring the production landscape of the industry with remarkable achievements such as "a 40% speed increase" and "a 2/3 space reduction". The aliases such as "combined assembly mold" and "intensive assembly mold" behind it also reflect the technical advantages in different application scenarios.

Dezhou Haitian Machinery: "Battery assembly mold" achieves a breakthrough in 7-hour molding

"Previously, the single mold production of prefabricated wall panels took 12 hours. Now, with our group assembly mold, the entire process from pouring to demolding can be completed in 7 hours." Dezhou Haitian Machinery's technical director Wang Lei held the latest production report and showed it to the reporter, demonstrating the efficiency leap of the equipment. This equipment, supported by the "13th Five-Year" National Key Research and Development Program, is called "battery assembly mold" by the front-line workers due to its compact arrangement of multiple assembly molds like a battery pack. This speed-up breakthrough stems from the collaborative innovation of three core technologies.

Firstly, the mold cavity adjustable technology breaks the limitation of traditional molds "one mold for one use". "In the past, to produce wall panels of different specifications, the entire set of molds needed to be replaced, and the debugging alone took 2 hours. Now, through hydraulic drive to adjust the side mold, 3 different sizes can be switched in 15 minutes, adapting to the production needs of wall panels ranging from 1.2 meters to 3 meters." Wang Lei explained that this technology fully releases the modular advantage of "combined assembly mold", increasing the equipment utilization rate to 92%, which is 18 percentage points higher than the industry average.

Secondly, the multi-source vibration mold system solves the contradiction between concrete density and forming speed. "Traditional assembly molds do not vibrate evenly, which easily leads to air bubbles and cracks, and requires an extension of the curing time. We set 6 sets of high-frequency vibrators on both sides and the bottom of the mold, and through intelligent control to adjust the amplitude and frequency, allowing the concrete to complete the dense forming within 30 minutes, reducing the time by half compared to traditional processes." Wang Lei said that this system also reduces the reliance on manual operation, with the labor cost of the vibration process reduced by 60%.

What is more noteworthy is that this equipment, as a typical "intensive assembly mold", demonstrates significant advantages in space utilization. In Dezhou Haitian Machinery's demonstration factory, the reporter saw that a group assembly mold production line occupying only 80 square meters had a daily production capacity of 350 square meters, while a traditional flat mold production line needed 240 square meters to achieve the same production capacity. "Currently, this equipment has been implemented in 20+ prefabricated component factories in Shandong and Hebei, and for a project using it to produce interior wall panels for public housing, the construction period was shortened by 28 days compared to the original plan." Wang Lei added.

Ai Li Company "Grouped column mold": Curing time halved, production capacity doubled

Coincidentally, Ai Li Company, which focuses on high-end forming equipment, has also achieved a technological breakthrough in its "grouped column mold" system recently. Unlike the "battery assembly mold" which focuses on the compact arrangement of multiple molds, Ai Li Company's "grouped column mold" is centered on "pre-fabricated component design", reducing the curing time from the industry's conventional 8-10 hours to 4 hours, doubling the production capacity.

"We found that the curing process of traditional group assembly molds has the problem of 'uneven heating', with molds closer to the steam pipe curing faster and those farther away curing slower, resulting in an overall longer cycle." Zhang Min, the R&D director of Ai Li Company, explained that the "grouped column mold" upgrade added independent temperature control channels inside the molds. Through sensors, it could monitor the temperature and humidity of each group of molds in real time, and then the intelligent system could adjust the steam supply to ensure that all mold cavities were in the same curing environment.

At a production site of a prefabricated component factory in the Yangtze River Delta, the reporter witnessed the effectiveness of this technology: A wall panel that was poured at 9 a.m. reached the demolding strength at 1 p.m., and the workers transported the wall panel to the storage area through an automatic demolding system. The entire process required no manual intervention. "Previously, we had two flat mold production lines, and the maximum production capacity was 120 wall panels per day. Now, a 'grouped column mold' production line can produce 240 panels, and it also saved 3 maintenance workers," said Li Gang, the production manager of the factory.

It is worth noting that this "grouped column mold" also integrates the modular advantages of "combined upright mold". It can be adjusted according to production capacity needs. "Customers can initially set up 6 groups of molds, with a daily production capacity of 180 panels. As subsequent orders increase, only 4 more groups of molds need to be added, and the daily production capacity can be increased to 300 panels. There is no need to rebuild the production line, and the equipment investment cost is reduced by 40%," Zhang Min said. Currently, this equipment has been exported to Southeast Asian countries such as Malaysia and Vietnam, adapting to the production of prefabricated components in high-temperature and high-humidity environments.

Hebei New Earth: "Combined upright mold" boosts project efficiency by 150%

In actual project applications, the speed-up advantage of the grouped upright mold is more prominent. The "combined upright mold" system of Hebei New Earth Building Technology Co., Ltd., in an apartment project in Qinhuangdao, created an industry record of a daily output of 2.5 cubic meters per person, an increase of 150% compared to traditional techniques.

This project needed to produce 18,000 interior wall panels. The schedule was tight, and the task was heavy. The traditional flat mold process required at least 60 people and 3 months to complete. We used 'combined upright mold', and in 35 people and 2 months, we completed it." Xie Wei, the project manager of Hebei New Earth, introduced. The "side mold automatic opening + automatic pouring" function of this system made the production process highly automated: The pouring machine precisely injected concrete into the mold cavity according to preset parameters, the side mold automatically clamped and fixed, and the vibration, curing, and demolding processes did not require manual intervention. Workers only needed to be responsible for material transportation and product inspection.

Xie Wei also mentioned that the flexibility of the "combined upright mold" played a key role in the project. "In the middle of the project, the client temporarily adjusted the thickness of some wall panels from 150 millimeters to 180 millimeters. If using traditional molds, at least a 3-day shutdown was required to replace the molds, but our 'combined upright mold' could complete the parameter setting in 2 hours and resume production on the same day, without delaying the schedule."

In addition, this "combined upright mold" also incorporated the spatial advantages of "intensive upright mold". "The project site was limited in space, and traditional flat molds required dividing the pouring area, curing area, and storage area, which occupied a large area. Our 'combined upright mold' production line integrated all functions and occupied only 120 square meters, and there was enough space reserved for storing finished products, significantly improving the management efficiency on site." Xie Wei said.

Industry upgrade: Grouped upright mold becomes the "efficiency engine" of prefabricated buildings

Many industry experts said that this speed-up breakthrough of the grouped upright mold (including combined upright mold, intensive upright mold, battery group upright mold, etc.) not only solved the pain points of "limited space, long cycle, and high cost" in prefabricated component production, but also promoted the high-quality development of the prefabricated building industry. Liu Jun, the director of the Building Industrialization Research Center of the China Academy of Building Research, pointed out: "In the past, due to the low production efficiency of prefabricated components, the cost of装配式 buildings was 5% to 8% higher than that of traditional poured buildings, which hindered the promotion of the industry. Now, the assembly of groups of molds has shortened the production cycle by more than 40%, and the labor cost has decreased by 30% to 50%. This effectively lowered the unit price of prefabricated components, gradually revealing the cost advantage of装配式 buildings."

According to industry data, in the first half of 2024, the penetration rate of intelligent assembly of groups of molds in China reached 28%, an increase of 10 percentage points compared to the same period last year. It is expected that it will exceed 35% within the year. At the same time, the export volume of assembly of groups of molds has also continued to increase. In addition to the Southeast Asian market, prefabricated component factories in countries such as New Zealand and Australia have also begun to introduce our "battery assembly molds" and "assembly of groups of columns" equipment, promoting the efficiency upgrade of the globalfabricatedbuilding industry.

"Going forward, assembly of groups of molds will also develop towards the 'intelligentization + greenization' direction," Liu Jun predicted. With the integration of digital twins and Internet of Things technologies, assembly of groups of molds will achieve real-time monitoring and intelligent optimization of the entire production process; at the same time, through technologies such as waste heat recovery and steam recycling, equipment energy consumption will further decrease, helping the

fabricatedbuilding industry achieve the "dual carbon" goals.