3D House Molds (PPVC) Reshape The Future Of Residential Buildings

At a crucial time when the traditional construction industry is undergoing transformation, an innovative construction technology called 3D house molds (PPVC) is quietly emerging, painting a brand new blueprint for the future of residential buildings. This technology breaks down buildings into individual three-dimensional modules that are precisely prefabricated in factories, completely changing the entire process from design to construction of houses.

Technical Core: A Paradigm Shift from "Construction" to "Manufacturing"

The essence of PPVC technology is to pre-manufacture various functional spaces of a residence, such as kitchens, bathrooms, and bedrooms, in a highly automated factory environment into complete "three-dimensional modules". These modules already incorporate all pipelines, interiors, and fixtures, meeting the standard of "ready for use upon completion". Subsequently, they are transported to the construction site and precisely hoisted and assembled like building blocks, quickly forming the main structure of the building.

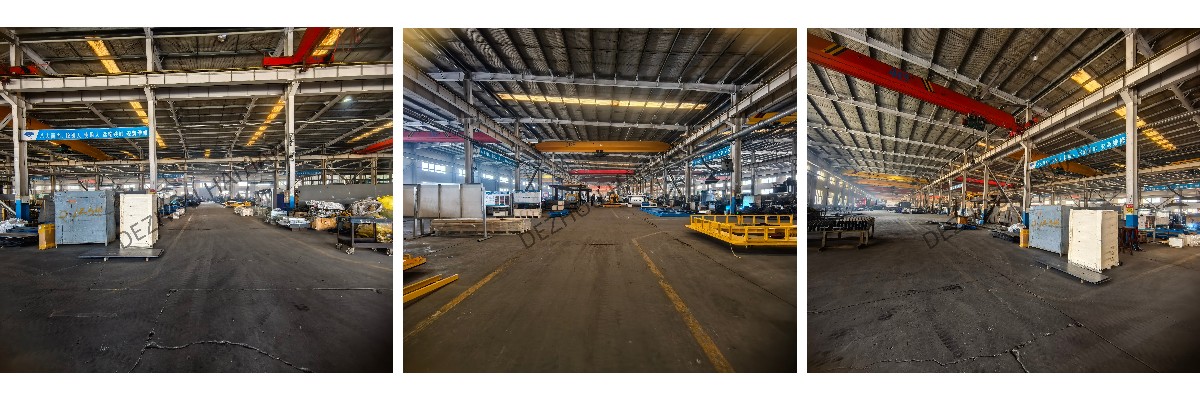

This model has significantly shifted the on-site wet construction to the controlled factory workshops, achieving an industrialized upgrade of the construction production method. It is not merely a change in construction tools, but rather a fundamental paradigm shift from the scattered and extensive "on-site construction" to the precise and efficient "factory manufacturing".

Multidimensional Value: Empowering Industry Sustainable Development

The transformative value brought by the PPVC technology is multi-dimensional. Firstly, in terms of quality and precision, the factory-based production environment overcomes the interference of weather and the volatility of manual operations, enabling each building module to achieve a uniformity and precision far exceeding traditional techniques, thereby enhancing the overall quality and durability of the residences from the very beginning.

Secondly, in terms of construction efficiency and on-site management, the synchronous prefabrication of modules and the rapid on-site assembly can significantly shorten the overall construction period. The construction site becomes orderly, construction waste, noise and dust are significantly reduced, and a cleaner and safer green construction environment is achieved.

Furthermore, this technology effectively addresses the contemporary issues of environmental protection and resource conservation. Factory-based production enables precise calculation and optimized utilization of raw materials, reducing waste; at the same time, standardized modules also facilitate the renovation, maintenance, and dismantling and recycling of future buildings, aligning with the concept of circular economy.

Future Outlook: Integration of Smart Construction and Personalized Needs

Looking ahead, the integration of PPVC technology with digitalization and intelligence will become increasingly seamless. From precise design based on BIM, to automated production by factory robots, to smart logistics and on-site drone hoisting, a fully digital-driven smart construction system is taking shape. This not only enhances efficiency but also accumulates valuable data assets, enabling comprehensive management throughout the building lifecycle.

At the same time, modularization does not imply a monotonous architectural style. Through flexible module combination methods, diverse exterior facade designs, and customized interior decoration, the PPVC technology can fully meet the modern residents' pursuit of the individuality and aesthetics of their residences, achieving the organic unity of "mass production" and "personal expression".