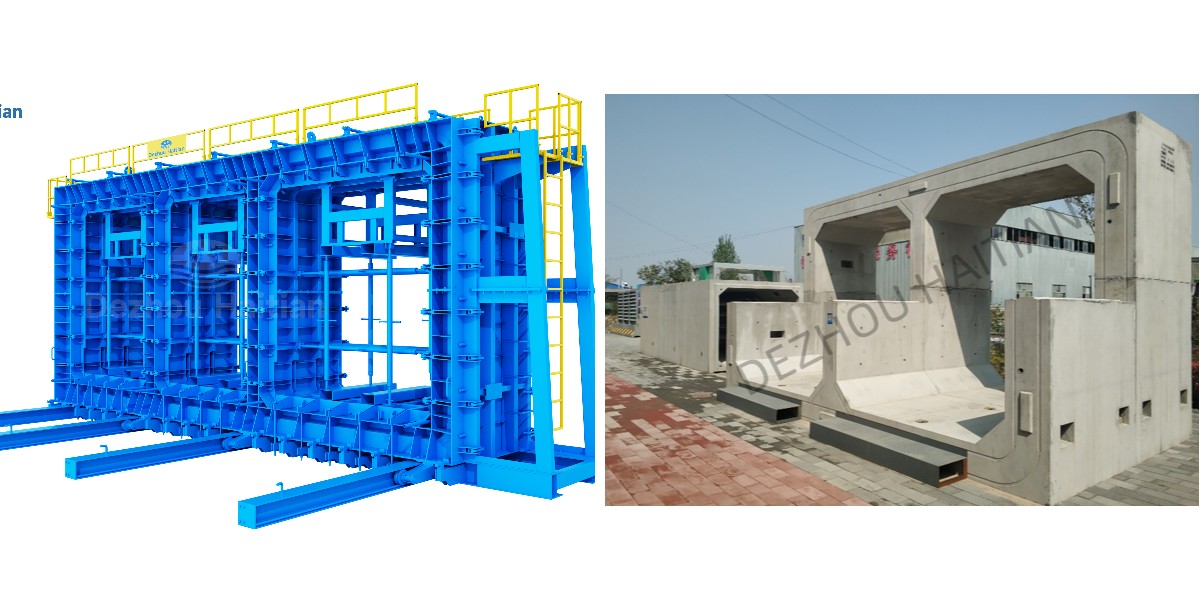

Precast Concrete Utility Tunnel Mould

1. Durable materials extend service life.

2. Ensures high precision in pipe gallery formation.

3. Simplifies operation and boosts production efficiency.

4. Compatible with various pipe gallery specifications.

5. Stable structure reduces maintenance.

The prefabricated concrete public facility tunnel mold is the core equipment for the prefabrication of municipal public facilities. It can precisely shape the overall structure of the tunnel and, when combined with customized usage plans, can seamlessly integrate into the production process of the prefabricated component factory, facilitating standardized construction. This mold features stable shaping and strong adaptability. It can meet different tunnel requirements without the need for complex adjustments and can also reduce post-construction adjustments, thereby improving production efficiency. It is widely used in municipal pipelines, underground pipe galleries and other projects. Customers have reported that the operation is convenient and the durability is excellent. Relying on the company's mature technology and comprehensive services, the prefabricated concrete public facility tunnel mold continues to meet industry standards. The company further enhances the reliability of the prefabricated concrete public facility tunnel mold by optimizing the mold design, providing customers with efficient and stable prefabrication solutions, and helping projects to be implemented with high quality.

The prefabricated concrete public facility tunnel mold, as the core equipment for the prefabrication of municipal public facilities, is specially designed for the standardized production of tunnel components. It can precisely shape the main structure of the tunnel and its compartments, as well as reserved holes, ensuring the consistency of the component formation. During use, a customized solution is adopted. In the early stage, the mold specifications are matched according to the project requirements. On-site installation and commissioning guidance is provided, and the process is carried out in a flow-based manner in conjunction with the prefabrication factory production line. Even beginners can quickly master the operation.

This mold features a modular design and high forming accuracy. It can be adapted to meet the requirements of different tunnel sections without complex modifications. Moreover, it is made of tough and wear-resistant material, and will not deform over a long period of use. Its core advantage lies in reducing the workload for post-processing of components, significantly improving production efficiency, and ensuring production safety with its stable structural design.

The product is widely used in projects such as municipal comprehensive tunnels, cable tunnels, and water supply and drainage tunnels. Many customers have reported that it is easy to operate and has outstanding durability, effectively reducing production costs. Relying on the company's mature R&D team and strict quality inspection procedures, the reliability of the prefabricated concrete public facility tunnel molds has withstood the test of long-term practice. The company also provides comprehensive after-sales maintenance services, continuously optimizing the performance of the prefabricated concrete public facility tunnel molds, and providing efficient and stable prefabricated solutions for various municipal projects.