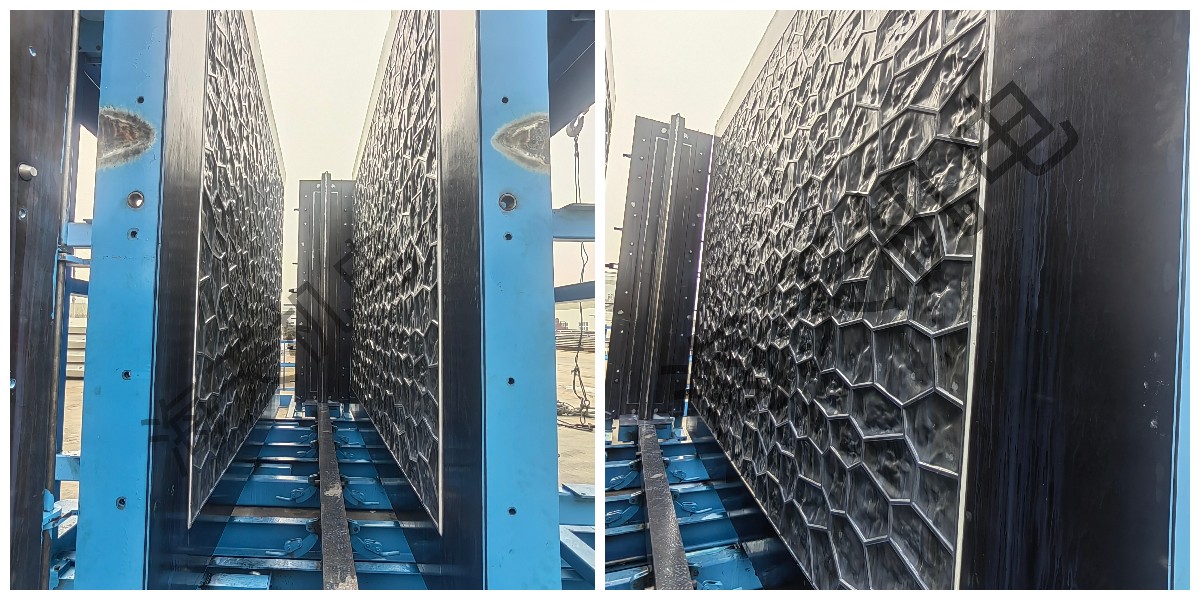

Battery Mould

1. Save floor space

2. High production efficiency

3. Excellent surface quality

4. Energy saving

5. Accept customization of different sizes

6. Applicable for production: various precast concrete solid wall panels and floor panels

The group forming mold developed by Haitian Machinery and Electronics has become a core equipment in the production of precast concrete wall panels due to its exquisite craftsmanship. This equipment adopts a modular design, with a stable and compact overall structure. When it is adapted for the production of precast concrete wall panel battery mould, it can achieve precise mould assembly and demolding actions, ensuring a stable and controllable forming process. Its unique sealing structure design can effectively prevent slurry leakage, and in combination with an intelligent temperature control system, it keeps the forming environment of the precast concrete wall panel battery mould in the optimal state, significantly improving the product forming quality.

The core advantages of the group forming mold lie in its efficiency and flexibility. Compared with traditional equipment, its integrated operation process can shorten the production cycle, and parameters can be quickly adjusted according to different specifications to adapt to the production scenarios of various concrete wall panel forming molds. The equipment is made of high-strength wear-resistant materials, and key components are specially treated, featuring excellent durability, which reduces maintenance costs during long-term use. At the same time, the equipment complies with environmental protection production standards, reducing dust and noise pollution during operation, and aligning with modern industrial green production concepts.

This group forming mold has a wide range of applications, suitable for the production of precast concrete wall panels in various building projects, such as residential buildings, commercial complexes, and industrial plants. It performs particularly well in large-scale prefabricated construction projects. Whether it is producing conventional concrete wall panels or adapting to special requirements for precast concrete wall panel battery mould and related components, it can demonstrate stable performance. Its convenient operation interface and reliable safety guarantee enable operators of different technical levels to easily operate, providing efficient and reliable solutions for various production enterprises.

Structural Design and Core Performance

The modular forming system developed by Haitian Machinery and Electronics has laid the foundation for the core advantages of prefabricated concrete wall panel production through refined design. The equipment adopts a modular architecture, with components closely connected and easy to disassemble and assemble. This not only shortens the commissioning period but also enables flexible adaptation to different production specifications. Regarding the forming characteristics of prefabricated concrete wall panel battery molds, the modular forming system is equipped with a precise transmission system, enabling smooth mold closing and opening actions. Combined with a real-time monitoring module, it can fully control the forming stability from the source, reducing product deviations. In terms of sealing design, the equipment adopts a customized elastic sealing component and multiple sealing methods, effectively preventing slurry leakage. Combined with an intelligent constant temperature control system, it can precisely adjust the environmental temperature and humidity according to the forming requirements of prefabricated concrete wall panel battery molds, providing the optimal working conditions for component forming and significantly improving the surface smoothness and structural density of the products.

Multi-dimensional Advantages and Industry Value

The competitive advantages of the modular forming system lie in the multi-dimensional integration of efficiency, durability, and environmental protection. In terms of efficiency, the equipment integrates the loading, forming, and curing processes into a single operation flow, which significantly reduces the time spent on process connections compared to traditional decentralized equipment. It is equipped with a parameter preset system, allowing for quick switching of production plans and adapting to various production scenarios of concrete wall panel forming molds, improving the turnover efficiency of the production line. In terms of durability, the key load-bearing components are made of high-strength alloy materials, which are hardened by quenching and processed by precise grinding, resulting in excellent surface hardness and wear resistance. They are not prone to deformation or wear during long-term operation, reducing maintenance frequency and operational costs. The environmental protection performance aligns with modern industrial requirements. The equipment is equipped with an efficient dust collection device and a low-noise transmission system, with dust and noise emissions far below industry standards. It uses an environmentally friendly solvent-free coating process, complying with mainstream environmental protection norms, providing support for enterprises to create green workshops.

Wide Application and Scene Adaptability

The application scope of the modular forming system has comprehensively covered prefabricated building and special component production fields, adapting to diverse scene requirements. In residential buildings, it can batch produce prefabricated concrete wall panels for internal and external walls, suitable for different building forms such as high-rise and multi-story buildings, meeting standardized construction requirements. In commercial complexes and industrial factory projects, it can precisely produce special components such as load-bearing walls and fireproof walls, adapting to large-span and high-load usage requirements. Especially in large-scale prefabricated construction projects, its stable batch production capacity and unified quality control can shorten construction cycles and improve project quality. For the production of components related to prefabricated concrete wall panel battery molds for new energy projects, the equipment can precisely adapt to the production of such components, relying on stable forming performance, providing high-quality components for energy storage stations, new energy factories, and other projects. The operation interface of the equipment is user-friendly, combined with intelligent fault warning and detailed guidance, adapting to operators of different technical levels, covering production scales from small workshops to large industrial enterprises.

.